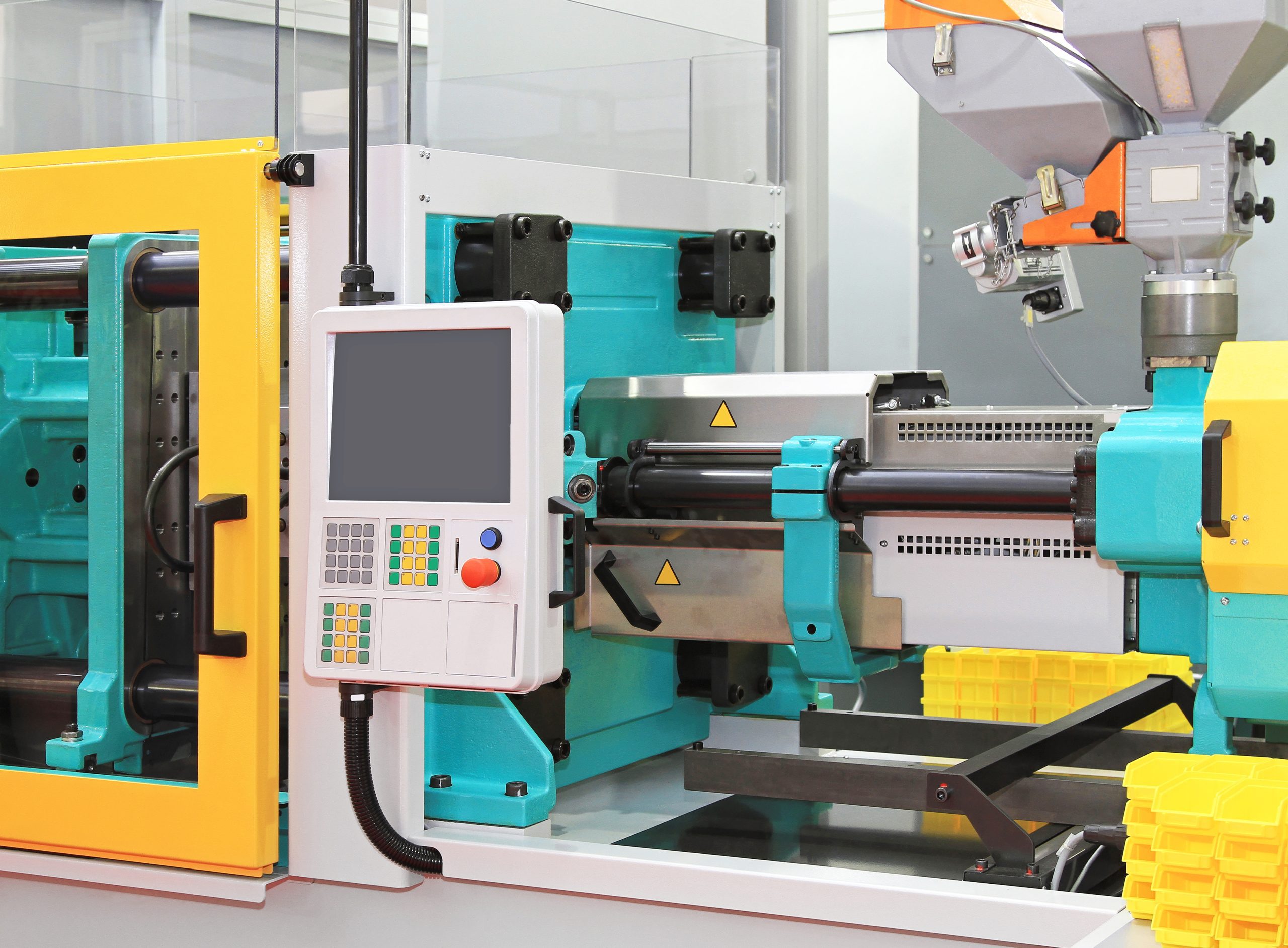

Our plastic injection molding process consistently produces high-quality parts with fast turnaround times ranging from 100 to 100,000 units.

Capabilities

-220 Ton Press

-Maximum mold size: 20″ X 19″ X 24″

-Minimum mold size: 12″ X 8″ X 9″

Our plastic injection molding process consistently produces high-quality parts with fast turnaround times ranging from 100 to 100,000 units.

Capabilities

-220 Ton Press

-Maximum mold size: 20″ X 19″ X 24″

-Minimum mold size: 12″ X 8″ X 9″

Dedoes’s fabrication team utilizes brake presses and punch presses to form a variety of metals to bring your creations to life.

Sheet Size and Specifications:

-Up to 48″ x 96″ sheet size

-Steel gauge up to 16 (0.064″)

Bending and Forming:

-Up to 48″ X 96″ sheet size

-70 to 100 Ton

Powder coating is a highly efficient method of finishing metal parts and a wide range of products to ensure a long-lasting, smooth finish. Our process involves the use of an automated conveyor line, washing system, powder coating, and curing for maximum efficiency, which can handle any job.

Dimension capabilities:

114″ (L) x 48″ (W) x 2″ (H).

Our assembly services include hand and power tool assembly, subassembly, complete assembly, and kitting. Dedoes can run production at a variety of volumes.

Dedoes’ Walled Lake facility is over 100,000 square feet of space, with 12 receiving doors, multiple cranes, versatile zones, and flexible lots; Dedoes makes warehousing a breeze.